Description

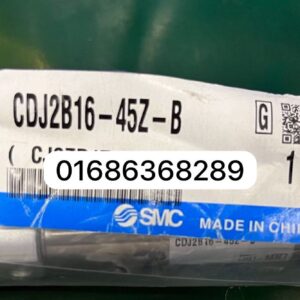

SMC CDQ2B32-20 PNEUMATIC CYLINDER Supplier in Bangladesh BD Importer in Bangladesh BD Price in Bangladesh BD

CQ2B12-15D(DZ/DM/DCM)

CQ2B12-20D(DZ/DM/DCM)

CQ2B12-25D(DZ/DM/DCM)

CQ2B12-30D(DZ/DM/DCM)

CDQ2B12-5D(DZ/DM/DCM)

CDQ2B12-10D(DZ/DM/DCM)

CDQ2B12-15D(DZ/DM/DCM)

CDQ2B12-20D(DZ/DM/DCM)

CDQ2B12-25D(DZ/DM/DCM)

CDQ2B12-30D(DZ/DM/DCM)

CQ2B16-5D(DZ/DM/DCM)

CQ2B16-10D(DZ/DM/DCM)

CQ2B16-15D(DZ/DM/DCM)

CQ2B16-20D(DZ/DM/DCM)

CQ2B16-25D(DZ/DM/DCM)

CQ2B16-30D(DZ/DM/DCM)

CDQ2B16-5D(DZ/DM/DCM)

CDQ2B16-10D(DZ/DM/DCM)

CDQ2B16-15D(DZ/DM/DCM)

CDQ2B16-20D(DZ/DM/DCM)

CDQ2B16-25D(DZ/DM/DCM)

CDQ2B16-30D(DZ/DM/DCM)

CQ2B20-5D(DZ/DM/DCM)

CQ2B20-10D(DZ/DM/DCM)

CQ2B20-15D(DZ/DM/DCM)

CQ2B20-20D(DZ/DM/DCM)

CQ2B20-25D(DZ/DM/DCM)

CQ2B20-30D(DZ/DM/DCM)

CQ2B20-35D(DZ/DM/DCM)

CQ2B20-40D(DZ/DM/DCM)

CQ2B20-45D(DZ/DM/DCM)

CQ2B20-50D(DZ/DM/DCM)

CDQ2B20-5D(DZ/DM/DCM)

CDQ2B20-10D(DZ/DM/DCM)

CDQ2B20-15D(DZ/DM/DCM)

CDQ2B20-20D(DZ/DM/DCM)

CDQ2B20-25D(DZ/DM/DCM)

CDQ2B20-30D(DZ/DM/DCM)

CDQ2B20-35D(DZ/DM/DCM)

CDQ2B20-40D(DZ/DM/DCM)

CDQ2B20-45D(DZ/DM/DCM)

CDQ2B20-50D(DZ/DM/DCM)

CQ2B25-5D(DZ/DM/DCM)

CQ2B25-10D(DZ/DM/DCM)

CQ2B25-15D(DZ/DM/DCM)

CQ2B25-20D(DZ/DM/DCM)

CQ2B25-25D(DZ/DM/DCM)

CQ2B25-30D(DZ/DM/DCM)

CQ2B25-35D(DZ/DM/DCM)

CQ2B25-40D(DZ/DM/DCM)

CQ2B25-45D(DZ/DM/DCM)

CQ2B25-50D(DZ/DM/DCM)

CDQ2B25-5D(DZ/DM/DCM)

CDQ2B25-10D(DZ/DM/DCM)

CDQ2B25-15D(DZ/DM/DCM)

CDQ2B25-20D(DZ/DM/DCM)

CDQ2B25-25D(DZ/DM/DCM)

CDQ2B25-30D(DZ/DM/DCM)

CDQ2B25-35D(DZ/DM/DCM)

CDQ2B25-40D(DZ/DM/DCM)

CDQ2B25-45D(DZ/DM/DCM)

CDQ2B25-50D(DZ/DM/DCM)

CQ2B32-5D(DZ/DM/DCM)

CQ2B32-10D(DZ/DM/DCM)

CQ2B32-15D(DZ/DM/DCM)

CQ2B32-20D(DZ/DM/DCM)

CQ2B32-25D(DZ/DM/DCM)

CQ2B32-30D(DZ/DM/DCM)

CQ2B32-35D(DZ/DM/DCM)

CQ2B32-40D(DZ/DM/DCM)

CQ2B32-45D(DZ/DM/DCM)

CQ2B32-50D(DZ/DM/DCM)

CQ2B32-75D(DZ/DM/DCM)

CQ2B32-100D(DZ/DM/DCM)

CDQ2B32-5D(DZ/DM/DCM)

CDQ2B32-10DZ/DM/DCM)

CDQ2B32-15D(DZ/DM/DCM)

CDQ2B32-20D(DZ/DM/DCM)

CDQ2B32-25D(DZ/DM/DCM)

CDQ2B32-30D(DZ/DM/DCM)

CDQ2B32-35D(DZ/DM/DCM)

CDQ2B32-40D(DZ/DM/DCM)

CDQ2B32-45D(DZ/DM/DCM)

CDQ2B32-50(DZ/DM/DCM)

CDQ2B32-75D(DZ/DM/DCM)

CDQ2B32-100D(DZ/DM/DCM)

CQ2B40-5D(DZ/DM/DCM)

CQ2B40-10D(DZ/DM/DCM)

CQ2B40-15D(DZ/DM/DCM)

CQ2B40-20D(DZ/DM/DCM)

CQ2B40-25D(DZ/DM/DCM)

CQ2B40-30D(DZ/DM/DCM)

CQ2B40-35D(DZ/DM/DCM)

CQ2B40-40D(DZ/DM/DCM)

CQ2B40-45D(DZ/DM/DCM)

CQ2B40-50D(DZ/DM/DCM)

CQ2B40-75D(DZ/DM/DCM)

CQ2B40-100D(DZ/DM/DCM)

CDQ2B40-5D(DZ/DM/DCM)

CDQ2B40-10D(DZ/DM/DCM)

CDQ2B40-15D(DZ/DM/DCM)

CDQ2B40-20D(DZ/DM/DCM)

CDQ2B40-25D(DZ/DM/DCM)

CDQ2B40-30D(DZ/DM/DCM)

CDQ2B40-35D(DZ/DM/DCM)

CDQ2B40-40D(DZ/DM/DCM)

CDQ2B40-45D(DZ/DM/DCM)

CDQ2B40-50D(DZ/DM/DCM)

CDQ2B40-75D(DZ/DM/DCM)

CDQ2B40-100D(DZ/DM/DCM)

CQ2B50-5D(DZ/DM/DCM)

CQ2B50-10D(DZ/DM/DCM)

CQ2B50-15D(DZ/DM/DCM)

CQ2B50-20D(DZ/DM/DCM)

CQ2B50-25D(DZ/DM/DCM)

CQ2B50-30D(DZ/DM/DCM)

CQ2B50-35D(DZ/DM/DCM)

CQ2B50-40D(DZ/DM/DCM)

CQ2B50-45D(DZ/DM/DCM)

CQ2B50-50D(DZ/DM/DCM)

CQ2B50-75D(DZ/DM/DCM)

CQ2B50-100D(DZ/DM/DCM)

CDQ2B50-5D(DZ/DM/DCM)

CDQ2B50-10D(DZ/DM/DCM)

CDQ2B50-15D(DZ/DM/DCM)

CDQ2B50-20D(DZ/DM/DCM)

CDQ2B50-25D(DZ/DM/DCM)

CDQ2B50-30D(DZ/DM/DCM)

CDQ2B50-35D(DZ/DM/DCM)

CDQ2B50-40D(DZ/DM/DCM)

CDQ2B50-45D(DZ/DM/DCM)

CDQ2B50-50D(DZ/DM/DCM)

CDQ2B50-75D(DZ/DM/DCM)

CDQ2B50-100D(DZ/DM/DCM)

CQ2B63-5D(DZ/DM/DCM)

CQ2B63-10D(DZ/DM/DCM)

CQ2B63-15D(DZ/DM/DCM)

CQ2B63-20D(DZ/DM/DCM)

CQ2B63-25D(DZ/DM/DCM)

CQ2B63-30D(DZ/DM/DCM)

CQ2B63-35D(DZ/DM/DCM)

CQ2B63-40D(DZ/DM/DCM)

CQ2B63-45D(DZ/DM/DCM)

CQ2B63-50D(DZ/DM/DCM)

CQ2B63-75D(DZ/DM/DCM)

CQ2B63-100D(DZ/DM/DCM)

CDQ2B63-5D(DZ/DM/DCM)

CDQ2B63-10D(DZ/DM/DCM)

CDQ2B63-15D(DZ/DM/DCM)

CDQ2B63-20D(DZ/DM/DCM)

CDQ2B63-25D(DZ/DM/DCM)

CDQ2B63-30D(DZ/DM/DCM)

CDQ2B63-35D(DZ/DM/DCM)

CDQ2B63-40D(DZ/DM/DCM)

CDQ2B63-45D(DZ/DM/DCM)

CDQ2B63-50D(DZ/DM/DCM)

CDQ2B63-75D(DZ/DM/DCM)

CDQ2B63-100D(DZ/DM/DCM)

CQ2B80-5D(DZ/DM/DCM)

CQ2B80-10D(DZ/DM/DCM)

CQ2B80-15D(DZ/DM/DCM)

CQ2B80-20D(DZ/DM/DCM)

CQ2B80-25D(DZ/DM/DCM)

CQ2B80-30D(DZ/DM/DCM)

CQ2B80-35D(DZ/DM/DCM)

CQ2B80-40D(DZ/DM/DCM)

CQ2B80-45D(DZ/DM/DCM)

CQ2B80-50D(DZ/DM/DCM)

CDQ2B80-75D(DZ/DM/DCM)

CQ2B80-100D(DZ/DM/DCM)

CDQ2B80-5D(DZ/DM/DCM)

CDQ2B80-10D(DZ/DM/DCM)

CDQ2B80-15D(DZ/DM/DCM)

CDQ2B80-20D(DZ/DM/DCM)

CDQ2B80-25D(DZ/DM/DCM)

CDQ2B80-30D(DZ/DM/DCM)

CDQ2B80-35D(DZ/DM/DCM)

CDQ2B80-40D(DZ/DM/DCM)

CDQ2B80-45D(DZ/DM/DCM)

CDQ2B80-50D(DZ/DM/DCM)

CQ2B80-75D(DZ/DM/DCM)

CDQ2B80-100D(DZ/DM/DCM)

CQ2B100-5D(DZ/DM/DCM)

CQ2B100-10D(DZ/DM/DCM)

CQ2B100-15D(DZ/DM/DCM)

CQ2B100-20D(DZ/DM/DCM)

CQ2B100-25D(DZ/DM/DCM)

CQ2B100-30D(DZ/DM/DCM)

CQ2B100-35D(DZ/DM/DCM)

CQ2B100-40D(DZ/DM/DCM)

CQ2B100-45D(DZ/DM/DCM)

CQ2B100-50D(DZ/DM/DCM)

CQ2B100-75D(DZ/DM/DCM)

CQ2B100-100D(DZ/DM/DCM)

CDQ2B100-5D(DZ/DM/DCM)

CDQ2B100-10D(DZ/DM/DCM)

CDQ2B100-15D(DZ/DM/DCM)

CDQ2B100-20D(DZ/DM/DCM)

CDQ2B100-25D(DZ/DM/DCM)

CDQ2B100-30D(DZ/DM/DCM)

CDQ2B100-35D(DZ/DM/DCM)

CDQ2B100-40D(DZ/DM/DCM)

CDQ2B100-45D(DZ/DM/DCM)

CDQ2B100-50D(DZ/DM/DCM)

CDQ2B100-75D(DZ/DM/DCM)

CDQ2B100-100D(DZ/DM/DCM)

CQ2B125-5D(DZ/DM/DCM)

CQ2B125-10D(DZ/DM/DCM)

CQ2B125-15D(DZ/DM/DCM)

CQ2B125-20D(DZ/DM/DCM)

CQ2B125-25D(DZ/DM/DCM)

CQ2B125-30D(DZ/DM/DCM)

CQ2B125-35D(DZ/DM/DCM)

CQ2B125-40D(DZ/DM/DCM)

CQ2B125-45D(DZ/DM/DCM)

CQ2B125-50D(DZ/DM/DCM)

CQ2B125-75D(DZ/DM/DCM)

CQ2B125-100D(DZ/DM/DCM)

CDQ2B125-5D(DZ/DM/DCM)

CDQ2B125-10D(DZ/DM/DCM)

CDQ2B125-15D(DZ/DM/DCM)

CDQ2B125-20D(DZ/DM/DCM)

CDQ2B125-25D(DZ/DM/DCM)

CDQ2B125-30D(DZ/DM/DCM)

CDQ2B125-35D(DZ/DM/DCM)

CDQ2B125-40D(DZ/DM/DCM)

CDQ2B125-45D(DZ/DM/DCM)

CDQ2B125-50D(DZ/DM/DCM)

CDQ2B125-75D(DZ/DM/DCM)

CDQ2B125-100D(DZ/DM/DCM)

CQ2B12-5D

The SMC CDQ2B32-20 is a compact pneumatic cylinder from SMC’s CQ2 series, known for its space-saving design and high performance. Below are the key specifications and details for the CDQ2B32-20 model:

Key Specifications

- Model Number: CDQ2B32-20

- Cylinder Type:

- Compact pneumatic cylinder from the CQ2 series, ideal for applications requiring a compact design with reliable linear motion.

- Bore Size:

- 32 mm (This refers to the internal diameter of the cylinder bore, which influences the force output of the piston).

- Stroke Length:

- 20 mm (The maximum distance the piston can travel, or the stroke length).

- Action Type:

- Double-acting (Air pressure is used to extend and retract the piston rod, allowing motion in both directions).

- Mounting Type:

- The CQ2 series supports various mounting options such as through-hole or tapped mounting, allowing easy installation into compact systems.

- Port Size:

- The air connection ports are generally 1/8″ BSP or NPT, depending on the regional standards and configuration.

- Operating Pressure:

- 0.1 MPa to 1.0 MPa (1 to 10 bar or 14.5 to 145 psi), offering a wide range of operating pressures for different applications.

- Operating Temperature:

- -10°C to +70°C (14°F to 158°F), making it suitable for general industrial environments.

- Cushioning:

- Rubber bumpers at both ends to cushion the piston stroke, reducing impact noise and wear.

- Piston Rod:

- The piston rod is typically made of stainless steel, ensuring durability and corrosion resistance, particularly in industrial environments.

- Built-in Magnet:

- The CD in the model number indicates the presence of a magnet in the piston for position sensing. This allows the use of auto-switches to detect the piston’s position for automation and feedback systems.

- Materials:

- Cylinder Body: Made from anodized aluminum for a lightweight and corrosion-resistant structure.

- Piston Rod: Stainless steel for high wear resistance and durability.

- Seals: High-quality elastomers like NBR (Nitrile Butadiene Rubber) for long-lasting performance.

Features

- Compact Design: The small form factor is perfect for applications where space is constrained.

- Double-Acting: Provides air-powered motion in both extension and retraction, making it versatile for a wide range of motion control applications.

- Magnetic Piston: Allows the cylinder to work with position-sensing auto-switches, which are crucial for applications requiring precise positioning or automation.

- High Performance: Despite its compact size, the CQ2 series offers strong output forces due to the high-quality design and material construction.

- Versatile Mounting Options: Through-hole or tapped mounting provides flexibility in how the cylinder is installed.

Applications

- Automation Systems: Used in various industrial automation settings where precise linear motion is required in tight spaces.

- Pick-and-Place Systems: Ideal for robotic systems that need reliable and repetitive linear motion.

- Assembly Lines: Common in industries where compact yet powerful actuators are required for positioning or moving parts.

- Packaging Machines: Utilized in compact packaging equipment where space is limited, but fast and reliable movement is essential.

- Medical Devices: The compact design and precision make it suitable for applications in medical equipment and laboratory automation.

Reviews

There are no reviews yet.